- Home

- Engineering

- Design Centre

- Fire Protection

- Healthcare Facilities Version 2.0

Firestop in healthcare

Fire protection and airflow control to help minimize risk in mission-critical facilities

Challenging requirements

When it comes to fire safety, hospitals are uniquely challenging projects. On the one hand, variations in the mobility of occupants mean that evacuation times must be maximized. On the other, modern hospitals contain complex and ever-changing building services. This demands passive fire protection and compartmentation measures which help to meet the strictest regulations and can allow critical rooms to remain in full operation after a fire incident.

Importance of passive fire protection

With dynamic and complex requirements for building services, the number of penetrations passing through fire rated walls and ceilings is typically high. Gaps in fire-rated walls and ceilings may represent a risk for patients, staff and equipment, as fire – and more importantly smoke – can spread rapidly.

Active fire protection alone, including detection (e.g. alarms) and suppression (e.g. sprinklers), may not be enough.

Containment of fire and smoke is also key: effective compartmentation can be achieved with passive fire protection.

Fire safety after a seismic event

Fire can be a common post-earthquake risk, as mechanical pipes and electrical cables can be damaged, releasing flammable contents or sparks. Hospitals are also critical in helping communities recover from earthquakes, so it’s important that they don’t experience significant damage or associated downtime.

Therefore, firestop products used for pipes, cables and joints, should be tested under seismic conditions and designed to withstand movement.

Keeping operating costs low

Healthcare is a sector under severe cost pressure with a duty to keep building life-cycle costs low. Hospitals are dynamic environments with constantly changing patient requirements and technological advancements. As new equipment is purchased and existing equipment is maintained or reconfigured, firestopping after every maintenance activity can be an uncalculated hidden cost.

On top of that, in critical rooms like Intensive Care Units the air pressure should remain stable. Therefore, the prevention of air leakage and every marginal efficiency gain can positively contribute to the reduction of the life-cycle cost of the building.

Firestop solutions that contribute to easier maintenance and airflow control can have a direct impact on your bottom line.

Sensitive surroundings

As well as the wide-ranging challenges of designing, building and maintaining healthcare facilities, there are also other significant challenges in ongoing operations. When looking to contain the spread of fire and smoke, there are other important considerations – such as infection control, airborne fibers and acoustics.

Infection control

Penetrations for services between patient rooms can represent a source of airborne bacteria transmission.

Therefore, airflow control must be carefully managed to help keep the air where it is intended to be and therefore reduce the spread of infection.

Virtually fiber-free

Commonly used traditional firestopping methods, like coated boards, are often composed of fibers of metallic ore and igneous rock. Whilst they can effectively prevent smoke and fire spreading, repenetrating these systems with pipes or cables may release fibers into the air, which could pose a risk to patients, particularly those in critical environments like operating theatres or intensive care units.

Noise reduction

Patient privacy, comfort and recuperation may be compromised when noise from adjacent spaces travels uninhibited. A main cause of these problems is the inadequate acoustic insulation between rooms.

Firestop products with superior acoustic insulation properties help contribute to the overall noise reduction.

Solutions for demanding applications

Hilti has over 30 years of experience in providing internationally tested and approved firestop systems for a wide range of mechanical, electrical and mixed penetrations applications.

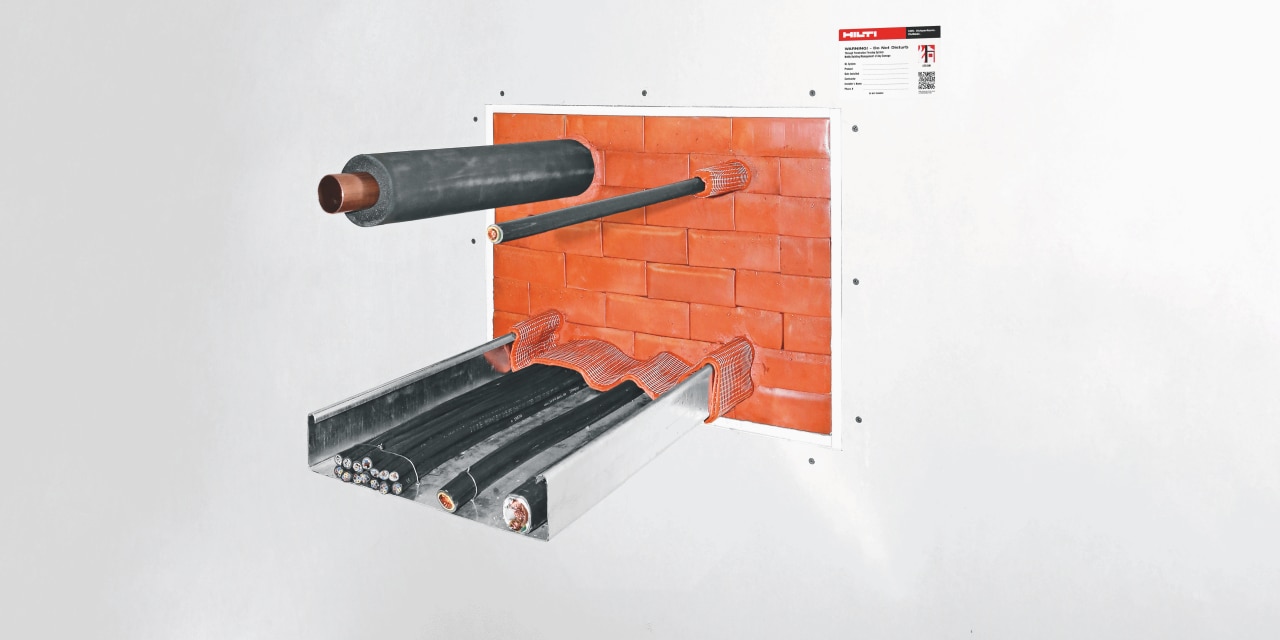

Mechanical applications

Solutions for wastewater, fresh water, heating and gas pipes:

CP 680-P Cast-In Device CFS-B Firestop bandage CFS-C P Firestop collar

Electrical applications

Solutions for electrical cables, cable bundles and conduits:

CP 606 Firestop Acrylic Sealant CFS-PL Firestop plugInnovative products for easy maintenance

Our extensively tested firestop products are quick and easy to install, designed to optimize construction time and help to reduce installation mistakes.

Their advanced design not only provides superior firestopping but also successfully addresses other pain points in a hospital environment, like airflow and noise control.

Firestop sleeve

Preformed, ready-to-use solution with no need for drilling or sealants. Industry-leading airflow control and easy cable changes thanks to its advanced twist mechanism. This helps to improve infection and dust control as well as energy efficiency.

Plus, you don’t need a firestop professional each time you move a cable, saving you time and money!

CFS-SL GA Firestop sleeve

Top track seal

For interior gypsum-board walls using metal frame construction, this firestop solution fills the gap between the metal and concrete surfaces. This means CFS-TTS has a high air-tightness performance, contributing to the airflow control thanks to its innovative composition that prevents cracks and other imperfections.

The all‐in‐one design helps to improve jobsite productivity.

CFS-TTS Top track seal

Cast-in device

Firestop cast-in devices make life easier compared to traditional methods of shuttering or breaking/coring after the concrete is poured. A one-step solution that maintains the opening and firestops the pipes at the same time.

Once installed, the device has an integrated water and smoke seal which impedes infections through standing water, as well as meeting high acoustic requirements.

CP 680-P Cast-in deviceNikolaj Pedersen

Production Manager

Engineering and Construction Services

Your firestop partner

Code compliant

Our products are designed to meet firestopping requirements of a wide range of international and national codes and approvals, such as UL, ETA, etc.

Many firestop products come with additional benefits, including mold and mildew resistance, thermal or acoustic insulation. Many also meet stringent environmental requirements to support green building standards, such as LEED® and BREEAM®.

On top of that, many of our firestop products have been tested according to the newly developed ASTM E3037 standard, which measures the performance of the products under movement and seismic conditions.

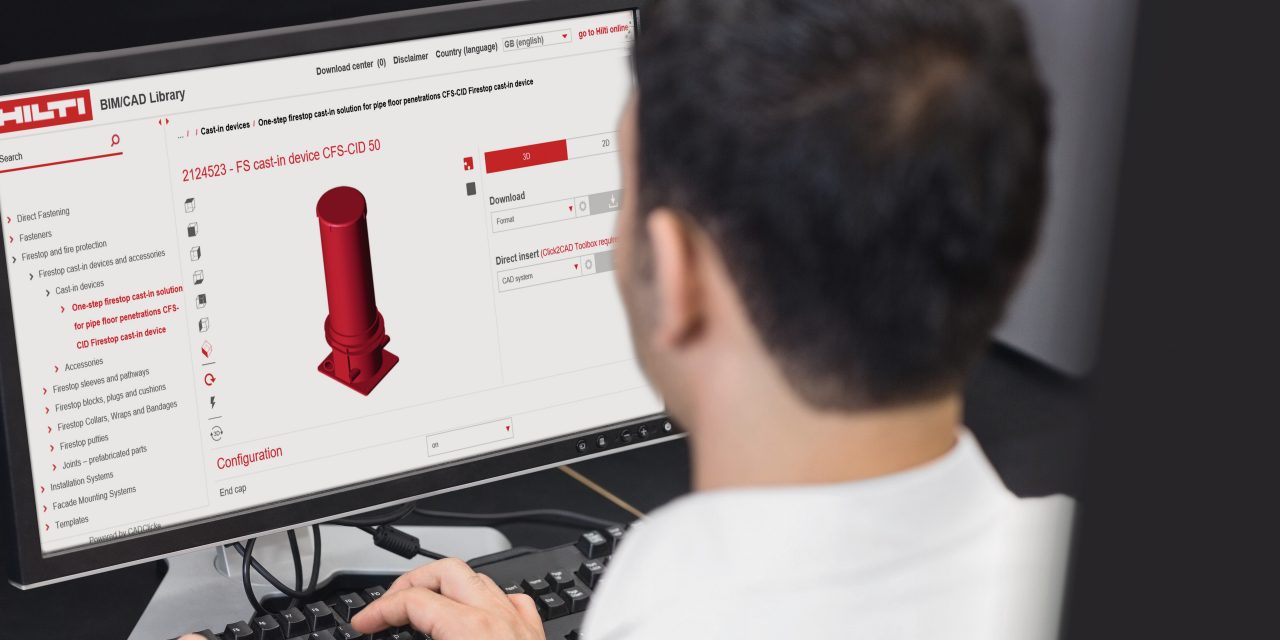

BIM / CAD Library

Hilti BIM / CAD library gives you access to Hilti products as 3D and 2D BIM / CAD objects. Simply integrate them directly into leading construction design software, such as AutoCAD® and Revit®.

More than just a library, it allows you to choose which country you want to design and work in, supporting global code compliance.

Documentation Manager

Hilti Documentation Manager allows you to securely record, track, and report on every installed firestop system – regardless of manufacturer.

You can markup digital floorplans, pull inspection reports, and collaborate with team members from anywhere on any device.

Engineering judgements

Hospitals can be highly bespoke buildings. Although our approvals cover a wide range of applications, there can be project-specific needs that are not approved by international guidelines. In this case, our experts help by providing engineering judgements covering the most demanding firestop applications.

On-site support and consultation

Highly skilled local engineers can be with you on-site during the construction phase to work with your teams and your subcontractors. Our local teams can also assist with any design, training or support required during execution.

We can also arrange installer training and issue training completion certificates.